Your Cart is Empty

Damage Control's Scientific Research with Sandia National Laboratories

May 18, 2016 3 min read 1 Comment

Operated for the U.S. Department of Energy by

Sandia Corporation

Albuquerque, New Mexico 87185-

date: 05/03/2011

to: Delano Romero, Albuquerque Delicate Dentistry

Jennifer DeGreef, 01933

from: Jim McElhanon, 01821

subject: NMSBA Program with Albuquerque Delicate Dentistry

Executive Summary:

Albuquerque Delicate Dentistry entered in to an NMSBA program with Sandia National Laboratories to evaluate four polymeric materials used as mouthguard materials for sports activities. Albuquerque Delicate Dentistry was interested in identifying the “best” energy absorbing material for fabrication into mouthguards and if a nominal thickness for the material could be determined. Sandia agreed to conduct a literature search on the materials and perform fundamental material property characterization on the four materials of interest. The four materials provided by Albuquerque Delicate Dentistry were 1) polyethyl vinyl acetate (EVA), 2) Black EVA, 3) [Damprotech] , an EVA containing a proprietary material, and 4) polytetrafluoroethylene (PTFE). Dynamic mechanical analysis (DMA) was performed on the four materials. The data revealed that [Damprotech] was the best energy absorption material of the four materials under evaluation.

Literature Study

Another study by Westerman et. al., compared impact data for EVA mouthguards (with a Shore Hardness of 80) with material thicknesses of 1, 2, 3, 4, 5, and 6 mm. The data showed that a thickness of 4 mm was substantially better in reducing the amount of transmitted forces compared to 1, 2, or 3 mm thicknesses. Increasing the material thickness to 5 and 6 mm only showed marginal improvement in reducing transmitted forces and that any improvement was statistically insignificant compared to a 4 mm thickness.

Dynamic Mechanical Analysis of Albuquerque Delicate Dentistry Materials

Albuquerque Delicate Dentistry provided four mouthguard materials for mechanical testing. They were 1) polyethyl vinyl acetate (EVA), 2) Black EVA, 3) [Damprotech] EVA containing a proprietary material, and 4) polytetrafluoroethylene (PTFE). The materials were tested using dynamic mechanical analysis (DMA). DMA is a technique used for the characterization of the viscoelastic properties of materials. DMA measures modulus (stiffness) and damping (energy dissipation) properties of materials as they are deformed under periodic stress. Each material was subjected to DMA at frequencies between 1, 2, and 5, Hz. Figure 1 shows the storage modulus data for each polymeric sample at the tested frequencies. From this data the glass transition temperature (Tg) was measured and is listed in Figure 1. The Tg is a quantitative measurement of the reversible transition in amorphous materials from a hard and relatively brittle state into a molten or rubber-like state. All EVA based materials had a Tg below room temperature, while PTFE had a Tg of 88 °C. What this reveals is what is qualitatively observed from each material; The EVA based materials are rubbery above their glass transition temperature (which includes room temperature and body temperature) while the PTFE sample is a rigid sample and only becomes rubbery at temperatures > 88 °C (Data not shown).

Figure 1. Storage modulus and glass transition temperature data for 4 mouthguard materials using DMA.

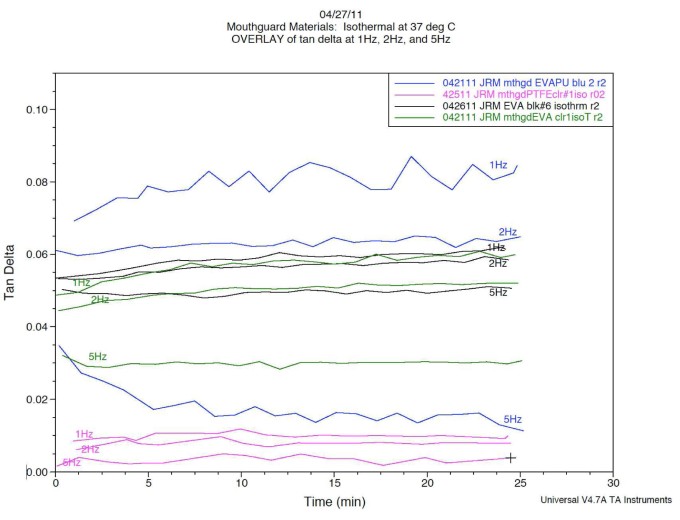

Figure 2 shows a plot of the tan delta data for each material at 37 °C (body temperature). The tan delta value is representative of the damping ability of the material. Damping is the dissipation of energy in the material under cyclic load. It is a measure of how well a material will be at absorbing energy, a critical property for mouthguard materials. Figure 2 shows that PTFE has the lowest tan delta relative to the other materials, therefore being the poorest material capable of absorbing energy. The two EVA materials (black and clear) show about 5 times improvement in tan delta and all measurements are quite similar for each material since they are chemically identical except in color. [Damprotech] , an EVA containing a proprietary material (EVAPU) shows the largest tan delta value at frequencies of 1 and 2 Hz. This data suggests that [Damprotech] would be a comparatively better energy absorbing material than EVA at low frequency.

Figure 2. DMA data of tan delta (damping ability) values for 4 mouthguard materials.

Summary and Recommendations

Our preliminary data and literature search suggests that [Damprotech] material is a superior energy absorbing material compared to commercial EVA products. The better energy absorbing behavior must be due to the added proprietary component in this particular EVA composite material. We have not conclusively determined what an optimal mouthguard thickness should be. Our literature search revealed that for EVA, the optimal energy absorbing thickness is 4 mm. Any increase in thickness beyond 4 mm provides little additional energy absorbing enhancement.

Deborah Taylor

May 21, 2016

I’ve worn Damage Control mouth guards for years. Does it make me roll better? No. Does it help protect my teeth? Yes!!!